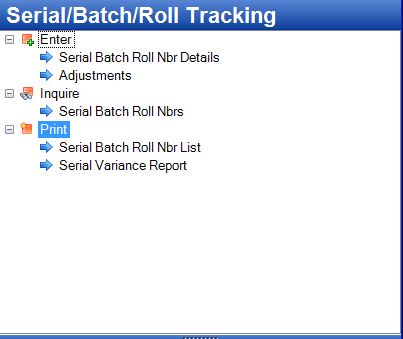

Serial Number Tracking

With Batch Number Tracking and Roll Number Tracking

Tencia’s Serial Number Tracking feature provides the mechanism to easily and immediately identify, monitor and track the movement of stock items by a unique characteristic such as a Serial, Batch or Roll number.

This feature is very valuable in manufacturing environments, when Bill of Materials is implemented, both raw materials and/or finished goods can be tracked by Serial, Batch or Roll Numbers.

Serial batch tracking feature includes:

- The ability to assess and track warranty claim conditions.

- To allocate Serial/Batch numbers to raw materials and finished goods.

- Optionally able to enter expiry dates and production batch details.

- Optionally allocate Serial, Batch or Roll Numbers during sales order entry.

- Optionally allocated Serial, Batch or Roll Numbers during production order entry.

- Monitor the actual cost of individual items, and this cost can optionally be the basis for the cost of sales calculation.

- Automatically allocate serial numbers.

- Ability to use oldest stock first according to expiry date.

- Bar code scanning features.

- Have Multiple Bin Locations per item.

- Perform global stock searches by Serial, Batch or Roll Numbers.

- Provision to record adjustments against, Serial, Batch or Roll Numbers.

- Serial, Batch or Roll number reports can be based on the status of individual numbers, including expiry date range, production batch range or quantity selections